LED PCB temperature

QuickField simulation example

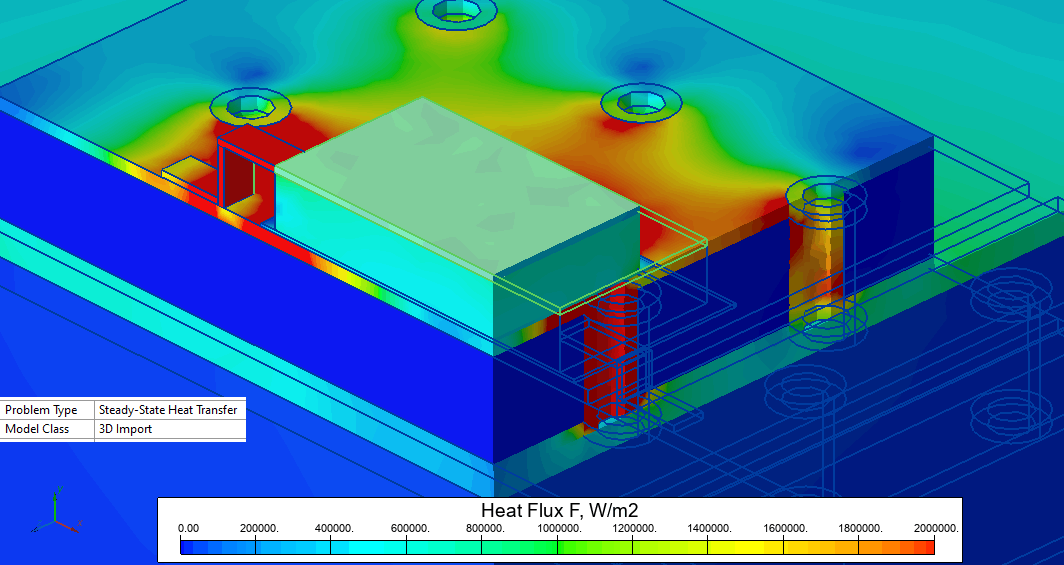

Light emitting diode is placed on the chip carrier board that is connected to the metal core printed circuit board. Thermal vias are used to provide low-resistance paths for the heat flux, helping to keep down the chip temperature.

Problem Type

3D problem of heat transfer.

Geometry

Given

Losses in the LED are 660 mW.

Ambient air temperature is T0 = 25°C, convection coefficient is α = 3.5 W/(K·m²).

| Aluminum | 138 | Copper | 390 |

| (Al In Ga N) chip | 50 | Si | 130 |

| Ag-Glue | 1.5 | FR-4 | 0.12 |

| MCPSB dielectric | 0.6 |

Task

Calculate the temperature distribution and thermal resistance.

Solution

The geometry features symmetry so it is possible to reduce the simulation domain by half.

At the bottom the massive heat sink is glued to the aluminum. We consider the bottom side to be at the constant temperature.

In 3D thermal problems QuickField allows to specify only the convection coefficient. To take into account the radiation we use linearization:

Radiation heat flux = ε·kSB·(T4 - T04) = ε·kSB · (T³ + T²·T0 + T·T0² + T0³) · (T - T0)

The term αradiation = ε·kSB · (T³ + T²·T0 + T·T0² + T0³) may be considered as an equivalent convection coefficient, where emissivity coefficient is ε = 0.9 and Stefan–Boltzmann constant is kSB = 5.67e-8 W/(m²·K4).

The expected chip temperature is T = +40°C. This yields αradiation = 5.8 W/(K·m²). On chip surfaces we specify (α + αradiation) convection coefficient.

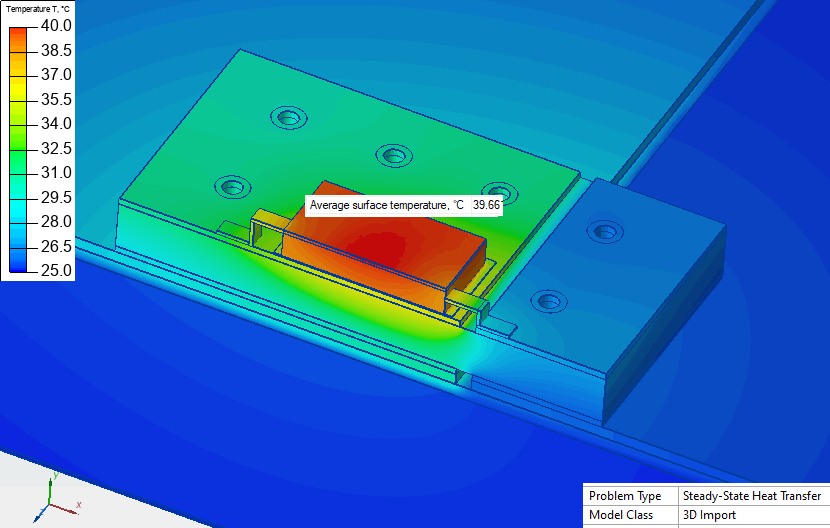

Results

LED temperature is +39°C, so our initial estimation was quite accurate. In case the assumed and calculated temperatures vary considerable we can recalculate the convection coefficient and run the analysis several times till the temperature value converges.

Thermal resistance = Temperature difference / heat flux = (39-25) / 0.66 = 21 K/W.

Reference:

Material properties and general idea of the example are taken from the paper by Langer, G.; Leitgeb, M.; et al. Advanced thermal management solutions on PCBs for high power applications, IPC Apex Expo (2014) Las Vegas, USA.

- Download simulation files (files may be viewed using any QuickField Edition).