Cable thermal conductivity

QuickField simulation example

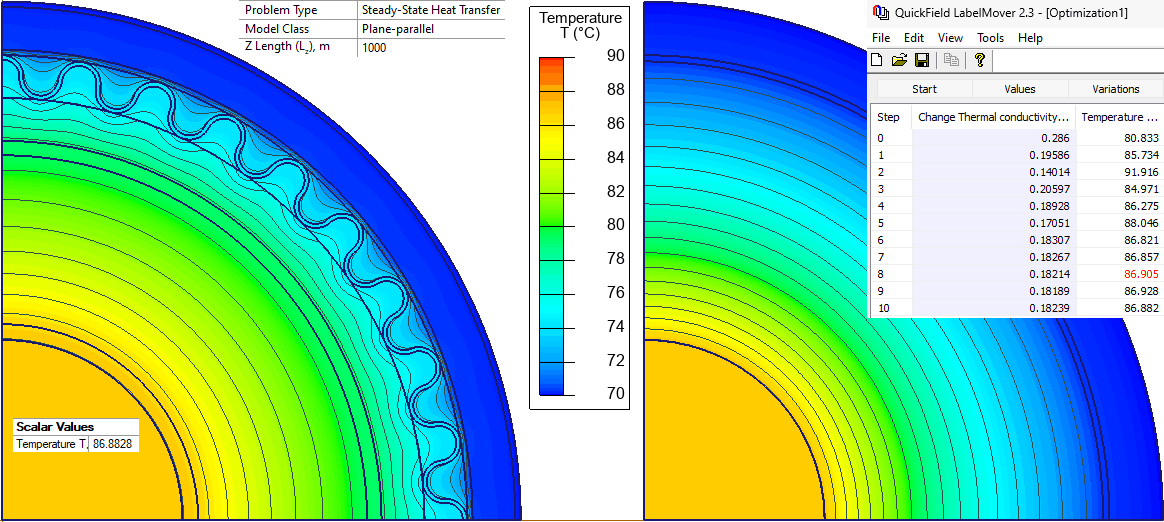

IEC 60287-2-1 [1] provides the method for calculation of the thermal resistance conductor to sheath of the cable. In this example we use a practical approach to simplify a cable structure and calculate the equivalent thermal resistance of the high voltage XLPE cable [2].

Problem Type

Plane-parallel problem of Heat transfer.

Geometry

Cable length is Lz = 1 km.

Two cable cross-sections are considered, original and simplified. Both models feature the same conductor diameter, external cable diameter and the sheath cross-section area.

Given

Conductor current is 800 A, frequency 50 Hz, resistance is 0.0321 Ohm/km.

Sheath current is 150 A. Aluminum sheath electric resistivity is 26.5 uOhm*mm, cross-section area is 157 mm².

| Item | Thermal conductivity [2], W/K*m |

|---|---|

| Conductor (copper) | 402 |

| Inner semi-conductive screen | 0.658 |

| XLPE | 0.286 |

| Outer semi-conductive screen | 0.491 |

| Buffer layer (water blocking strip and the air gap) | 0.09 |

| Aluminum sheath | 230 |

| Anti-corrosive layer | 0.024 |

| HDPE jacket | 2.28 |

| Outer conductive screen | 0.41 |

Task

Calculate the equivalent thermal conductivity of the cable between the conductor and sheath.

Solution

Power loss in the conductor is Pconductor = Current² * Resistance = 800² * 0.0321 = 20.5 kW per 1 km of the cable length.

In QuickField we specify power density Qconductor = Pconductor / (Lz * Cross-section area) = 20500 / (1000 * π·0.0337²/4) = 23 kW/m³.

Electrical resistance of the sheath is R = electric resistivity * Lz / Cross-section area = 26.5e-9 * 1000 / 157e-6 = 0.169 Ohm/km.

Power loss in the sheath is Psheath = 150² * 0.169 = 3.8 kW/km.

In QuickField we specify power density Qsheath = Psheath / (Lz * Cross-section area) = 3800 / (1000 * 157e-6) = 24.2 kW/m³.

We specify temperature at the cable surface of +70°C and simulate the original model and calculate the temperature of the conductor.

Then we use the LabelMover tool to perform the optimization of the simplified model. The goal is to adjust thermal conductivity of the dielectric so that the conductor temperature matches the conductor temperature value calculated in the original model.

Results

Conductor surface temperature is 86.9°C. Equivalent thermal conductivity of the dielectric is λ = 0.182 W/(K·m).

Thermal resistance conductor to sheath = Temperature difference / Heat flux = (86.9 - 70.18) / 20.5 = 0.816 K*m/W.

It may be compared with the thermal resistance conductor to sheath calculated in accordance with IEC 60287-2-1: T1 = (1/λ/2/π) * LN(1 + 2*t/d) = (1/0.182/2/3.142) * LN(1 + 2*26.02/33.7) = 0.816 K*m/W.

References:

[1] IEC 60287-2-1 Electric cables - Calculation of the current rating - Part 2-1: Thermal resistance - Calculation of thermal resistance.

[2] Xin, Yue & Lei, Jiang & Zhao, Xiyuan & Li, Wenbin & Gao, Jinghui & Xi, Baofeng & Zhong, Lisheng & Xia, Linfeng., Cause Analysis of Aging Ablation on Sheath of 110 kV Single Core High Voltage Cable, 2019.

- Download simulation files (files may be viewed using any QuickField Edition).